Oh my, this is a scary topic that may take you back to Physics 101 and visions of Blaise Pascal and Bernoulli’s Law. We don’t mean to cause dyspepsia so we will try to keep it basic. A basic understanding of hydraulic power is helpful in understanding how a bucket truck works.

In a nutshell, hydraulic fluid is pretty much incompressible, so when a force is applied to it at one end, like say, by moving a joystick attached to the upper control valve, the fluid moves through tubing and arrives at its destination undiminished, ready to do its work. If its destination is a cylinder, the fluid can easily move a piston within a cylinder to lift the boom. By the way, we just explained Pascal’s Law. See, that wasn’t so bad.

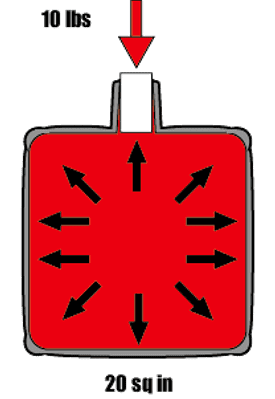

Getting back to Physics 101, we’re sure you remember that Force = Pressure x Area. Before your eyes glaze over, notice from the equation that as the area increases, so does the force. Think about it … if a small force (10lbs) is applied to a small area (1 square inch), the pressure applied would be transmitted through the hydraulic fluid and arrive at its destination with the force of 200 lbs on an area of 20 square inches. The possibilities are endless!

As you might imagine, not just any tubing will work for this kind of work. Bucket truck manufacturers recommend Type H nylaflow tubing. It is made of the stiffest of all nylons and has a burst pressure of 2,500 psi. Utility Equipment Parts offers nylaflow tubing as well as other parts and accessories for your bucket truck, including augers & auger tooling, buckets & liners, winch ropes and even hard to find parts.

And not just any hydraulic fluid will work for your bucket truck. You need high-grade aircraft hydraulic oil that meets Military Spec H5606. Don’t worry, your hydraulic shop knows what you need. All the major oil companies offer it, including Chevron, Mobil, Pennzoil, and Shell.

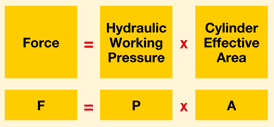

So how do these laws of physics translate into real work performed by a bucket truck? We know that Force = Pressure x Area. Let’s apply that formula to the main lift cylinder – the cylinder that is typically positioned at the base of the lower boom.

A typical hydraulic working pressure (P) for a bucket truck is about 3,000 psi, and the lift cylinder’s effective area might be 21 square inches … you’re gonna have to trust us on that. Here’s what that looks like in our formula.

Force = 3,000psi x 21 square inches = 63,000 lb

Think about that! By moving a joystick to make a cylinder lift the boom of a bucket truck, we have 63,000 lbs of force to work with. It kinda makes you feel powerful, doesn’t it?

Ok, that’s it. In our next class we’ll discuss Einstein’s Theory of Relativity.

The “UEP” Guys

We Know Parts and some Science too!

We Know Parts and some Science too!