Now that winter is over … time to “get the lead out” and the AIR!! What does that mean anyway … “get the lead out?!” Oh well, back to the important part of this blog. 😉

Have you ever tried working the upper controls of your bucket truck and the system seems sluggish? It’s a frustrating thing because you just can’t get the boom to move as much as you want it to – the system doesn’t respond crisply. Obviously, your first step is to consult the unit’s maintenance manual. A blocked control orifice could be causing your problem, or you may have air in the lines that carry hydraulic fluid.

For bucket trucks that have a pilot control system, like Teco, MAT3, and Hi-Rangers, it may be necessary to bleed air out of the pilot system from time to time. These units have ¼” nylaflow tubing that carries hydraulic fluid the full length of the boom, from upper controls to lower controls. Air can get in the system when you change tubing or when a fitting is leaking.

Not all bucket trucks employ a pilot control system. Some popular units like Altec, Versalift, and the Hi-Ranger XT use a full pressure system at the platform and use non-conductive hoses instead of ¼” tubing. The hoses are typically 3/8 inch or sometimes 1/2 inch. The systems are different, but equally as popular, depending on who you talk to.

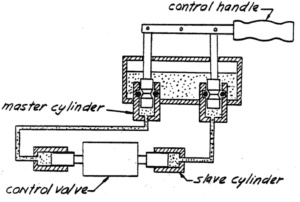

Unlike the older Teco machines and also Mat3 units that used a power-assist mechanism, the older Hi-Ranger control system employed a master/slave cylinder configuration. The upper platform control is the master and the lower control valve the slave. When the upper control piston (i.e. up/down function) is moved, say ¼”, the corresponding lower control valve piston moves the same ¼”. If it doesn’t, there is probably air in the system that is limiting the response.

Examples of How to Bleed a Line

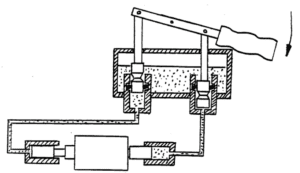

These drawings will give you a visual as we describe how to bleed the lines for a Hi-Ranger master/slave configuration.

With the control handles in the neutral position (not engaged), the outriggers down, and the booms in the stowed position, the person at the lower control valve station needs to engage the interlock palm button. That sets in motion a low flow of hydraulic oil (at about 30 psi) through the super-charger (seventh) pilot line from the lower control valve up to the platform control head base. Each of the lower valve sections has an end cap with a bleeder thumb screw. By loosening one of the thumb screws, hydraulic fluid starts to flow from the platform control head base through the pilot line down to the lower control valve and out the bleeder vent hole in the end cap. This flow of hydraulic fluid will cause any air in that line to escape through the bleeder vent hole in the end cap. Allow the oil to flow for a few minutes to ensure there are no air bubbles coming out of the bleeder vent hole and you have a steady stream of hydraulic oil.

Do the same thing for each of the boom functions. There are typically three sections to the lower control valve, with an end cap on each end of the section. One end cap for upper boom up and the opposite end cap for upper boom down. If all of the air has bled out, any handle movement above will have an equal movement below.

It’s a one-man job to bleed this system, but it is a two-man job to check if you have all of the air bled out of the pilot lines. To check the response of the platform control, have one man in the platform move the control head handle full motion for an individual function and have another man check to see that the lower control valve handle for that function moves full stroke. If the lower control valve has some additional motion, there is still some air in the pilot line that needs to be bled out. Repeat this check for all six functions.

There you have it, now go out and trim some trees and have a safe, happy Spring!

If you would like more information about how Utility Equipment Parts can help with getting parts and accessories for your unit, regardless of its age, contact the UEP Guys today.

You can also contact Utility Equipment Parts (UEP) for parts and accessories for your digger derrick or crane or read more about hydraulics.

You can also contact Utility Equipment Parts (UEP) for parts and accessories for your digger derrick or crane or read more about hydraulics.

We Know Parts!!

A special thank you to John Mlaker from Utility Truck Equipment & Parts for his expertise in helping to write this blog!