It’s relatively easy to install a utility pole. Hydraulic drilling equipment and augers have made a big difference. But sometimes an existing pole may need to be removed. How best to do that? Well, this is pretty easy too with today’s hydraulic tools.

Hold that thought … let’s talk about utility poles first. They support overhead power lines, electrical cable, fiber optic cable, transformers, even necessities like street lights and traffic lights. Obviously, utility poles are very important to our daily lives. A standard pole is about 40 feet long and buried 6 feet in the ground. Depending on the obstructions and clearance needed, utility poles can be as high as 120 feet.

Many utility poles are made of treated wood. Even so, wood does decay over time. The average life of a utility pole is 25-50 years, depending on factors like climate and soil condition. But the most significant cause of wood pole deterioration is woodpeckers.

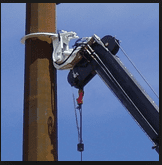

Getting back to removing utility poles, one way is to use a boom truck equipped with a hydraulic pole claw. Once the pole claw is tight around the pole, secure the pole with a sling rope and start loosening and pulling. One problem … this is pretty tough on a boom truck. It’s not made for removing utility poles.

The truck can be seriously damaged and even worse, there is potential for personal injury. Imagine if the violent rocking action needed to remove a pole caused the pole to break. It has happened, and a nearby lineman was injured.

The potential for equipment damage is great when removing poles using excessive force and rocking action. Typical damages include bent boom sections, premature winch line failures, bent sheave heads, and even failed rotation bearings. One utility company found that better than 43% of their truck maintenance was due to boom-related damages, including failed rotation bearings costing in excess of $17,000.

One other factor to consider: using a bucket truck to remove utility poles ties up heavy equipment for hours possibly, and requires a work crew that could be doing something else.

A better, more efficient way to remove poles is to use a portable pole puller. They are small, but they pack a punch with a very strong hydraulic cylinder. Portable pole pullers are precision-engineered, using the hydraulic tool line from a bucket truck. They do very well even in difficult terrain where a larger truck may not have access.

Utility Equipment Parts offers the Tiiger Pole Puller which weighs in at a mere 57 lbs., it is lightweight and easy to maneuver. It requires a standard low pressure hydraulic supply limited to a maximum of 2800 psi. We recommend 3/8” low pressure hydraulic hoses connected to a male and female flat face ½” NPT coupler.

The heart of this system is the Tiiger Pole Puller hydraulic cylinder, a real dynamo with a lift capacity exceeding 50,000 pounds. The cylinder is manufactured with high-strength steel tubing and a hard chrome-plated piston rod. Two handles make for an ergonomic design resulting in low handling stress for the operator. A 16-inch stroke means two to three lifts and you have successfully removed the pole. Other core parts include:

- Swivel and Hook Assembly

- Pole Puller Pad

- Base Plate

the UEP Guys also handles Tiiger accessories such as the Tiiger Cube, Tiiger Pole Dolly, ground drivers/sockets, cage organizers, and clamshells. More information about these accessories is available.

Compare that to a boom truck with a 40,000 ft-lb. derrick and a 20-ft. extension. This is a big machine that has a lifting capacity of 50,129 lbs. Oh, did we mention that the portable Tiiger Pole Puller has a lift capacity exceeding 50,000 lbs? Hmmm, seems like a no-brainer.

The “UEP” Guys We Know Parts!!