Modern Digger Derrick

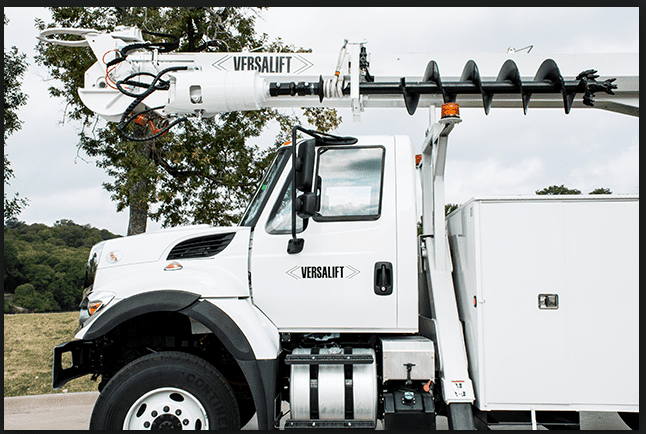

If you had a chance to read History of Digger Derricks, Part 1, you know that a digger derrick is essentially a mobile machine with a digger derrick mounted on a truck chassis. It is extremely large due to the physical dimensions and heavy weight of the attached boom pedestal and booms, the hydraulic motor, auger, and accessories. The digger truck has a powerful engine to multiply the torque and control the hydraulic system, which in turn directs the rotational capacity of the auger.

We gave a brief digger derrick history starting in the early days of electrification when power line construction was a manual process. It’s interesting to note that the 50’s and 60’s saw three innovations that are still in use today … 1) the auger storage bracket, 2) pole-grabbing winch, 3) hydraulic collector block. The latter allowed digger derricks to rotate continuously, without restriction, making for a much more versatile machine. Soon after, there were two more important innovations – the box-constructed boom and dual lift cylinders.

Modern digger derricks can be mounted on a customer’s specified chassis and have sheave heights over 100 ft and winch capacities of 60,000 lb. Some of these monstrous machines are equipped with 48-inch augers! These trucks are also engineered to include platforms and top controls for use as people-carriers and material handlers.

By being able to position a person in the air, modern digger derricks are now also used for maintenance work, including replacing cross-arms on utility poles, as well as construction work like erecting signs, lights and telecommunication lines.

Crews can now operate the machines remotely using radio controls. Modern digger derricks has more fiberglass components to improve insulation for safe and more productive work around energized power lines. Features such as advanced hydraulic systems for improved efficiency and controllability and boom tip configurations, such as “transferable tilt pole plummer,” to aid work practices are also innovations incorporated into today’s digger derricks.

You wouldn’t want to send a boy to do a man’s job … or vice versa. For that reason, Terex has come up with a capacity calculator which allows utility companies and contractors to select the right size of digger derrick to complete the majority of their day-to-day tasks — digging holes and setting poles. The calculator takes into account not only the digger derrick’s boom lifting capacity, but it also accounts for a modern digger derrick’s auger digging and lifting capacity. The truck should be able to dig a hole and set the pole without the need to reposition the digger derrick.

Contact Utility Equipment Parts (UEP) today for your digger derrick needs or any other parts and accessories for your bucket truck or crane.

The UEP Guys  We Know Parts!!

We Know Parts!!