Did you know the Hi Ranger joystick, aka the “pistol grip” has been used on bucket trucks long before kids began moving Mario and Luigi from room to room with Play Station controllers?

Known as “the Cadillac of bucket trucks,” the story of Hi-Ranger bucket trucks demonstrates their ability to innovate from the start. The story of the bucket truck’s pistol grip, demonstrates why they have one of the best and long-lived reputations in the utility equipment industry.

In the mid 1950’s, Lester Myers worked at the Mobile Aerial Towers plant in Ft. Wayne, IN. This plant was the original factory for Hi-Ranger bucket trucks and the location where he invented and then patented the upper control pistol grip assembly for the early Series 4 and 5 Hi-Ranger bucket trucks. The pistol grip modification allowed the user to perform more than one function from the same grip – up/down/rotate.

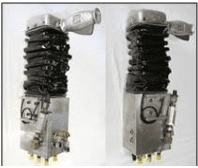

Those of us that work with, supply parts for, or go up in Hi-Ranger bucket trucks can appreciate how much the pistol grip has done to make work easier for those in the tree trimming and utility industries. The picture to the left shows how far the pistol grip mechanism advanced over the years – this one is from the early 1990’s.

Another unique and popular feature on the early history of Hi-Ranger bucket trucks was “compensated boom movement” where the movement of the joystick corresponded directly to the movement of the booms. These early machines employed a compensating chain and sprocket assembly that connected the turntable (i.e. base of unit) to the upper boom via the lift cable. This configuration added flexibility for maneuvering the bucket. The compensating chain mechanism has since been replaced by a special compensating hydraulic cylinder, making the independent movement of the lower and upper booms even easier.

Compensated boom movement allowed the upper boom to remain horizontal while the lower boom was being raised, allowing flexibility in lining up the bucket for use. This coupled with the single handle joy stick made it easier for the operator to move where he intended to go. Talk about versatility and maneuverability!

The early bucket trucks had a steel upper boom that was wrapped in fiberglass for contact insulation. In the early 1960’s, utility equipment makers such as Hi-Ranger, recognizing the need to improve electrical safety, manufactured bucket trucks with all fiberglass upper booms. This was a big innovation, but the steel lower boom was still not adequately insulated, making ground personnel vulnerable if the lower boom came in contact with a live wire.

The all steel lower boom was installed on early Hi-Ranger units like the 4D, 4F, 5TD, 5F, and 6TD. The 5TD unit was even offered with an insulated fiberglass turntable ring that provided chassis insulation in the event the elbow steel came in contact with an energized power line.

In the history of Hi Ranger, the next innovation appeared in the early 70’s; Hi-Ranger began manufacturing units like the 4FI, 5FI, and the 6TDI with a lower boom that incorporated a fiberglass insert between two steel sections. This innovation was incrementally perfected over the next 15 years, making ground personnel safer from electrocution. The popular 5FI unit was replaced by the 5FA series in 1988.

In 1983, the Hi-Ranger line was sold and moved its operations to Waukesha, WI. Shortly thereafter they introduced the 5H unit, followed a few years later by the 5HA series. In the mid ‘80’s Hi-Ranger came up with the power-assist feature for upper and lower controls. Prior to the controls operating with power assist, it was sometimes a feat of strength to operate the controls in cold weather.

Prior to the mid 1980’s Hi-Ranger units incorporated an accumulator – a fluid storage reservoir that housed hydraulic fluid and kept it under pressure, ready for use. In the mid ‘80’s the accumulator system was replaced by a variable volume piston pump which allowed for efficiency as well as simplicity. As you might expect, hydraulic pumps have also been improved and enhanced over the years.

The History of Hi-Ranger Bucket Trucks and the line’s performance continued to show strength and innovation, even after the line was purchased by Terex Utilities in 1992, and continued to be a leader and innovator. That was around the time when the XT series over-center aerial device was introduced. The term “over-center” refers to the position of the upper boom when it is fully extended and actually breaks past the 90-degree mark … it goes over center. This function gives an operator the ability to extend the lower and upper boom out vertically, thus having almost twice the amount of side reach capacity.

In the early 2000’s Terex introduced the hydraulic lift unit, or elevated unit. This innovation raised the whole boom mechanism, allowing aerial devices to add about 15 feet of working height without adding additional boom length. The hydraulic lift mechanism has the look of a large scissors jack.

So much for the history of Hi-Ranger Bucket Trucks … now our, admittedly shameless UEP plug. We can supply all your Hi-Ranger bucket truck parts needs. This even includes older units – all the way back to the 1960’s. We also offer a rebuild service for Hi-Ranger pistol grip controls, and for that matter, we also offer the rebuild service for most other makes of bucket trucks.

But if you’ve got a leaky control and all you need is a seal kit, we can help there too. We will actually answer the phone when you call. UEP has a motto that we stand by – Prompt, Responsive Service … Guaranteed Every Day! Contact Utility Equipment Parts today for your Hi-Ranger or any bucket truck need

The “UEP” Guys We Know Parts!!